INDUSTRIAL MECHANICS

LTI: Industrial mechanics company at your service for your projects

Our experience as a contributor in various industrial sectors, including district heating, chemistry, food processing, and many others, has led us to manage complex projects requiring the coordination of multiple trades, including industrial mechanics. Since our founding in 2015, our passion for innovation and excellence has allowed us to develop operational expertise essential for carrying out large-scale projects for our clients. We have developed technical processes, from design and custom manufacturing to commissioning and maintenance of various industrial mechanical systems.

Our industrial mechanical services

LTI combines its various expertise in industrial piping, high-pressure welding, design, and machining to meet your needs in industrial mechanics. We specialize in the execution of custom projects tailored to the specific requirements of each of your activities.

Custom design of mechanical assemblies

Whether it’s for new works such as the construction of machine rooms subject to DESP, or the replacement of mechanical subassemblies during maintenance operations, our design office (engineers, designers, and specialized industrial draftsmen) is capable of custom designing the necessary components in response to a strict set of specifications. From defining the required materials to calculating assemblies, we offer our expertise in chemistry, mechanics, and engineering to meet your needs.

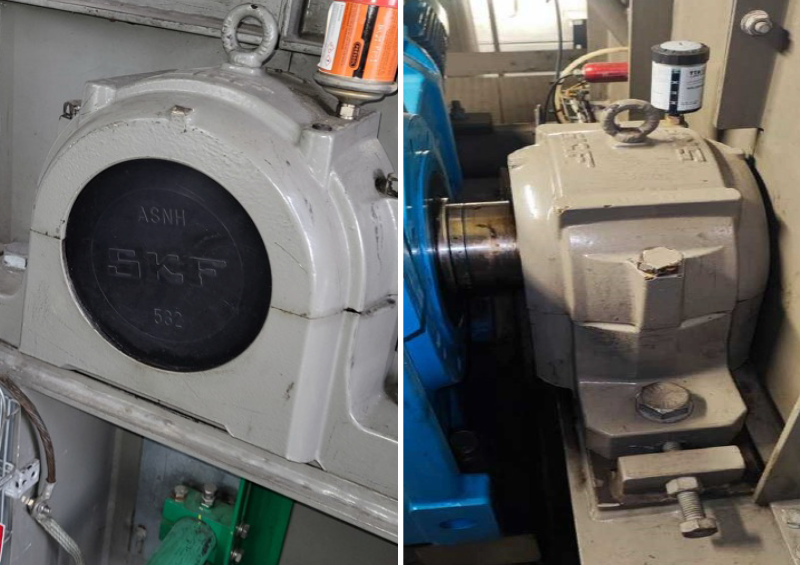

Machining, assembly, and mechanical welding

Machining, assembly, and mechanical welding are of paramount importance in industrial mechanics. Every project is based on precise machining plans, detailing dimensions, positions, and surface conditions to ensure that the finished part meets design requirements. Our workshops have controlled environment zones, allowing us to carry out the industrial assembly of subcomponents ourselves. During this stage, we precisely assemble complex parts to create metal structures of all sizes. Each part, machine, or mechanical assembly is systematically inspected and tested before being put into service, particularly the welds according to established standards.

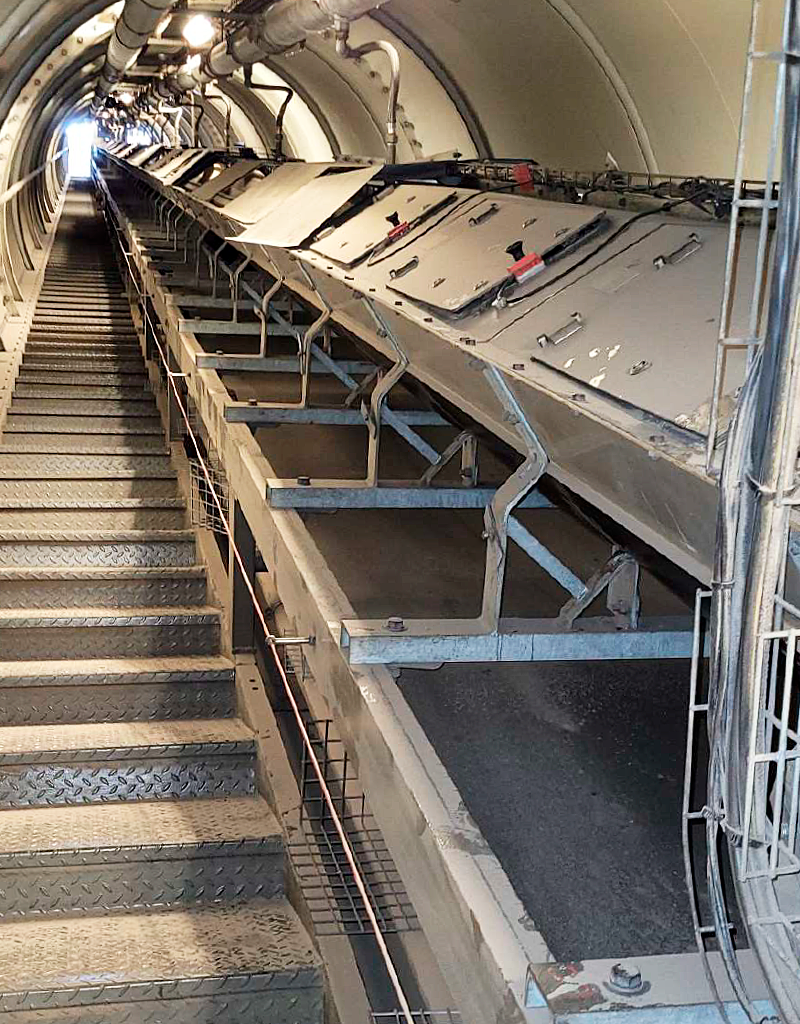

Some of our achievements in France

A dedicated and available team

Customer service and proximity

Although LTI is capable of managing large-scale projects, we have managed to maintain a local service, a human-sized company whose primary goal is customer satisfaction.